In the dynamic landscape of the food industry, the demand for efficient and reliable methods of preserving food has given rise to innovative technologies. Among these, the retort machine stands out as a key player, enabling the mass production of shelf-stable, long-lasting packaged foods. This article explores the fundamental aspects and functionalities of retort machines, shedding light on their significance in the food processing sector.

A retort machine is a specialized piece of equipment designed for the thermal processing of packaged foods. At its core, the primary objective of a retort machine is to sterilize food products by subjecting them to elevated temperatures in a sealed container. This sterilization process ensures the elimination of harmful microorganisms, bacteria, and enzymes that could otherwise lead to spoilage.

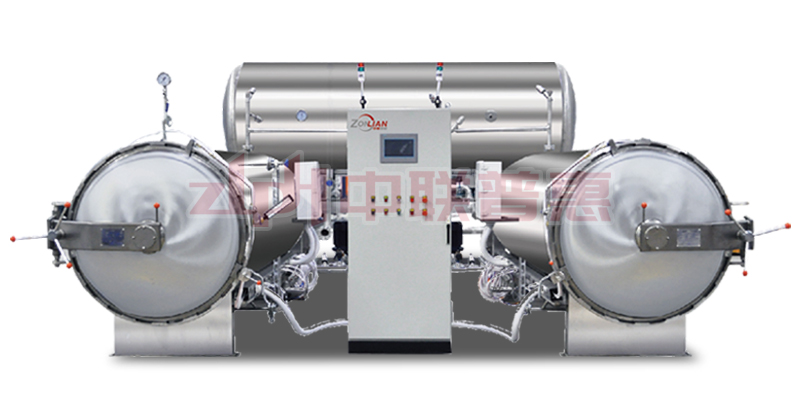

The operation of a retort machine involves a series of carefully controlled steps. First, food products are securely sealed in containers, commonly metal cans or glass jars, protecting them from external contaminants. These sealed containers are then loaded into the retort machine.

Retort machine utilizes a heating medium, often steam or hot water, to raise the temperature within the retort chamber. The controlled application of pressure helps achieve higher temperatures than those possible at atmospheric pressure, ensuring thorough sterilization. Modern retort machines are equipped with advanced automation and control systems, allowing for precise management of temperature profiles, cycle times, and other critical parameters.