-

HOME

- ABOUT US

- PRODUCTS

- FACTORY

-

SOLUTIONS

-

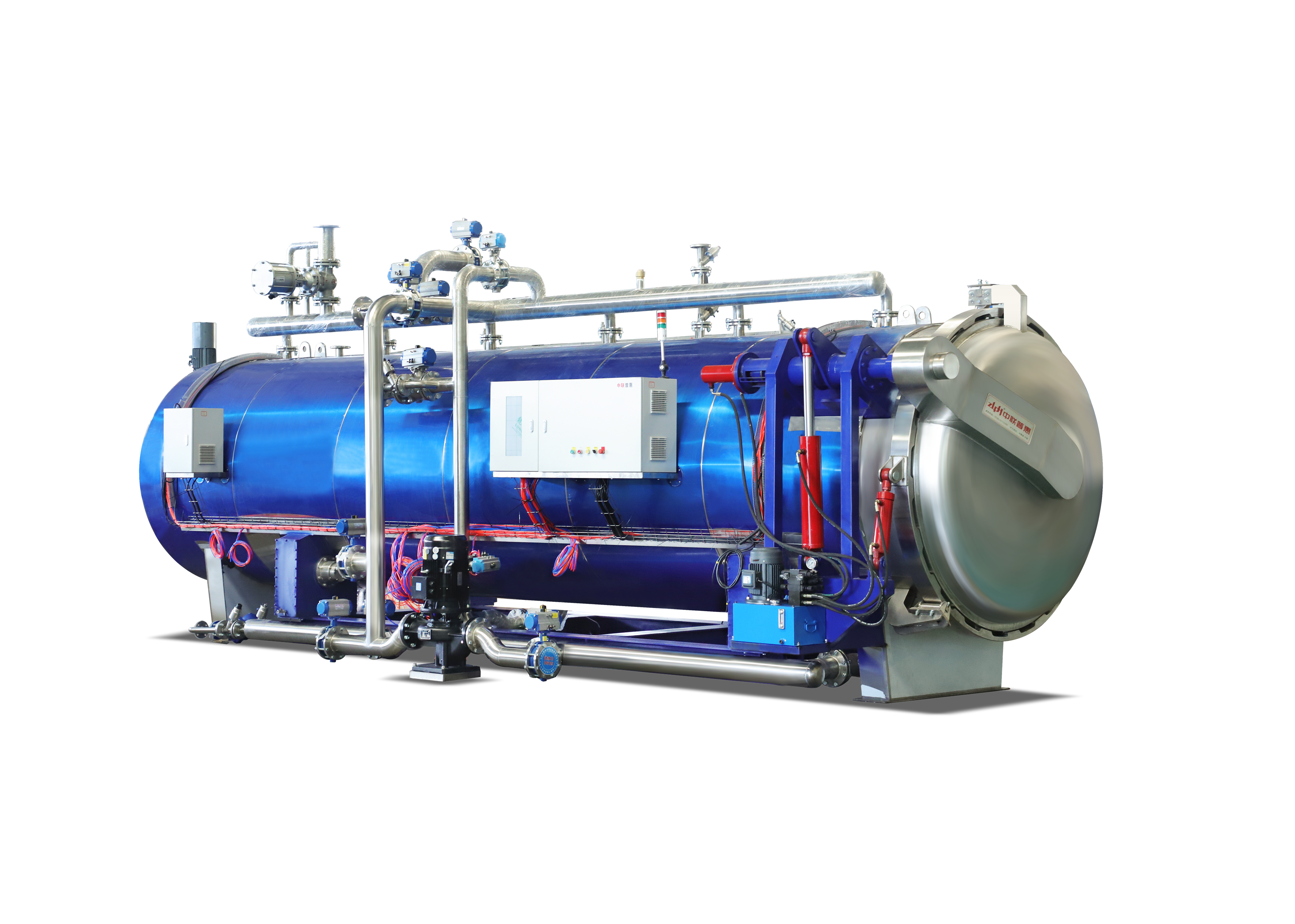

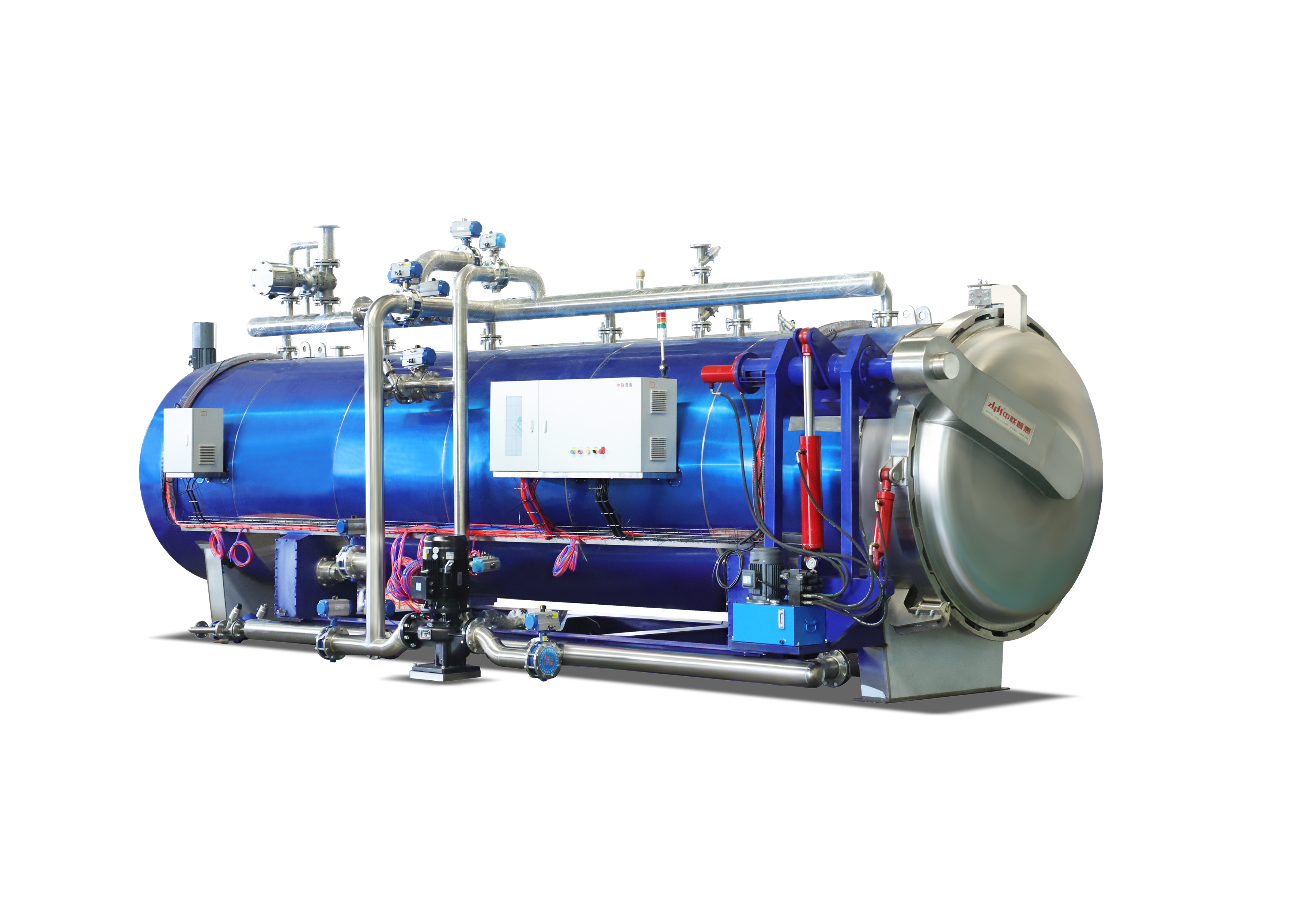

Customized canned sterilization production line

-

Customized canned sterilization production line

-

Customized glass bottles beverage sterilization production line

-

Customized PP/HDPE bottles beverage sterilization production line

-

Customized pouch snack food sterilization production line

-

Customized pouch food sterilization production line

-

Customized canned sterilization production line

-

PROJECTS

- NEWS

-

CONTANT US

English

Español

Nederlands

العربية

Pусский

Deutsch

日本語

Português

Français

Italiano

한국어

ภาษาไทย

Ελληνική γλώσσα

w języku polskim

Български

eesti

dansk

suomen

česky

în limba română

slovenski jezik

svenska

magyar

हिन्दी

Türk

tiếng việt

فارسی

עברית

slovenčina

Indonesia

Lietuvių

Latviešu

Melayu

Norsk

Українськи

اردو

hrvatski

বাংলা ভাষার

తెలుగు

தமிழ்

српски језик

Wikang Tagalog

Íslensku

Català

Монгол

Language

English

Español

Nederlands

العربية

Pусский

Deutsch

日本語

Português

Français

Italiano

한국어

ภาษาไทย

Ελληνική γλώσσα

w języku polskim

Български

eesti

dansk

suomen

česky

în limba română

slovenski jezik

svenska

magyar

हिन्दी

Türk

tiếng việt

فارسی

עברית

slovenčina

Indonesia

Lietuvių

Latviešu

Melayu

Norsk

Українськи

اردو

hrvatski

বাংলা ভাষার

తెలుగు

தமிழ்

српски језик

Wikang Tagalog

Íslensku

Català

Монгол

Menu

- HOME

- ABOUT US

- Company Culture

- Certificate

- Exhibition

- Service

- Delivery

- PRODUCTS

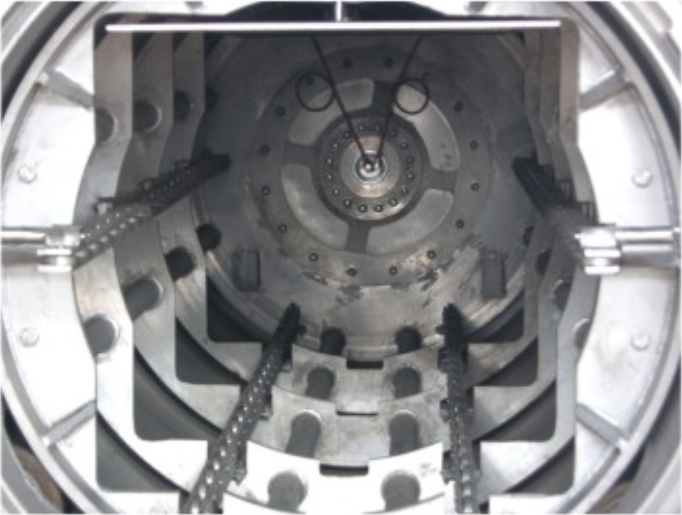

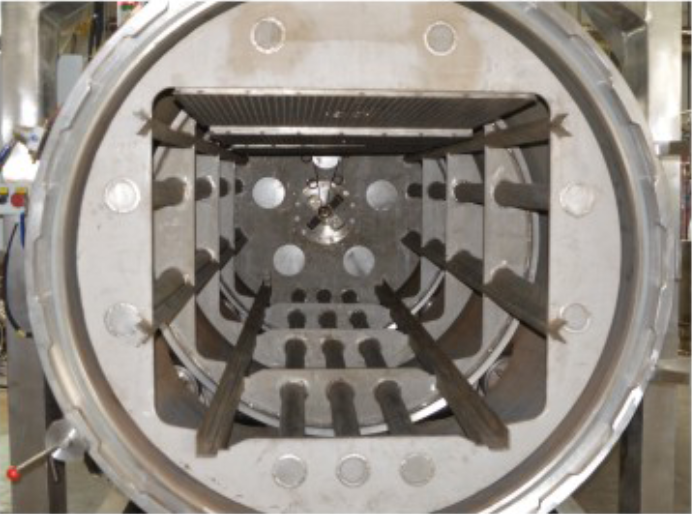

- Retort Autoclave

- Continuous Retort Line

- Retort loader Unloader System

- Customized Retort Line

- FACTORY

- Company Size And Office Environment

- Manufacturing Equipment

- SOLUTIONS

- Customized canned sterilization production line

- Customized canned sterilization production line

- Customized glass bottles beverage sterilization production line

- Customized PP/HDPE bottles beverage sterilization production line

- Customized pouch snack food sterilization production line

- Customized pouch food sterilization production line

- PROJECTS

- NEWS

- INDUSTRY NEWS

- EXHIBITION NEWS

- CONTANT US

Search